Product

All Product Categories

Plastic film

Plastic film is a common packaging material, which is lightweight, flexible, transparent and durable, and is widely used in various industries. The following are the product details of plastic film, including materials, characteristics, application fields and technical parameters:

Product Video

Product Catalog

- 1. Material classification

Polyethylene (PE) film:

Features: good flexibility, high transparency, water resistance, oil resistance, and strong chemical stability. According to different densities, it can be divided into high-density polyethylene (HDPE), low-density polyethylene (LDPE) and linear low-density polyethylene (LLDPE).

Polyvinyl chloride (PVC) film:

Features: high transparency, good shrinkage, good flexibility, strong chemical resistance, but it may release harmful substances at high temperatures and is not suitable for direct contact with high-temperature food.

Polypropylene (PP) film:

Features: high transparency, strong heat resistance, light weight, hard, suitable for high-temperature processing.

Polyester (PET) film:

Features: superior mechanical properties, good heat resistance, high transparency, corrosion resistance, and good gas barrier properties.

- 2. Technical parameters

Thickness: Depending on the specific application requirements, the thickness of plastic film is usually between 10 and 200 microns. Thinner plastic films are mostly used for lightweight packaging or food preservation, while thicker films are suitable for heavy packaging or industrial use.

Width: Customizable, conventional widths range from 100mm to 3000mm, suitable for different packaging machines and packaging needs.

Tensile strength: Plastic film has good tensile properties, especially PE and PET materials, usually with a tensile strength of 10 to 30 MPa, which can meet the needs of bundling or wrapping heavy goods.

Light transmittance: Transparency is one of the important properties of plastic film. Different materials have different light transmittances. PE and PP films usually have a light transmittance of 80% to 95%, while PVC film has a higher transparency, which can reach more than 90%.

Shrinkage: PVC and PET films have good heat shrinkage and are suitable for close packaging of labels and product exteriors. The shrinkage is usually 30%-50%.

- 3. Features

Flexibility: The flexibility of plastic film makes it suitable for packaging of items of various shapes, especially PE film, which can withstand certain stretching and deformation.

Self-adhesion: PE wrapping film has self-adhesion, which is suitable for bundling goods and keeping them stable.

Gas barrier properties: PET film and multi-layer co-extruded plastic film have excellent gas barrier properties, which can effectively extend the shelf life of food and prevent oxygen and moisture from entering the packaging.

Moisture resistance: Most plastic films have good moisture resistance and are suitable for waterproof packaging, such as food and pharmaceutical packaging.

Chemical resistance: Polyethylene and polypropylene films are acid-resistant and alkali-resistant, suitable for packaging chemicals, detergents, etc.

- 4. Environmental protection and sustainability

With the improvement of environmental awareness, the degradability and environmental protection of plastic films have become important considerations. At present, degradable plastic films have appeared on the market, especially biodegradable films based on PLA (polylactic acid), which have the characteristics of being completely degradable and suitable for replacing traditional non-degradable plastic films such as PE and PP, and are used in food packaging and daily necessities packaging.

- 5. Advantages

Light weight: Plastic film has the characteristics of being lightweight, which can reduce packaging weight and logistics costs.

Low cost: Compared with packaging materials such as metal and glass, the production cost of plastic film is low and cost-effective.

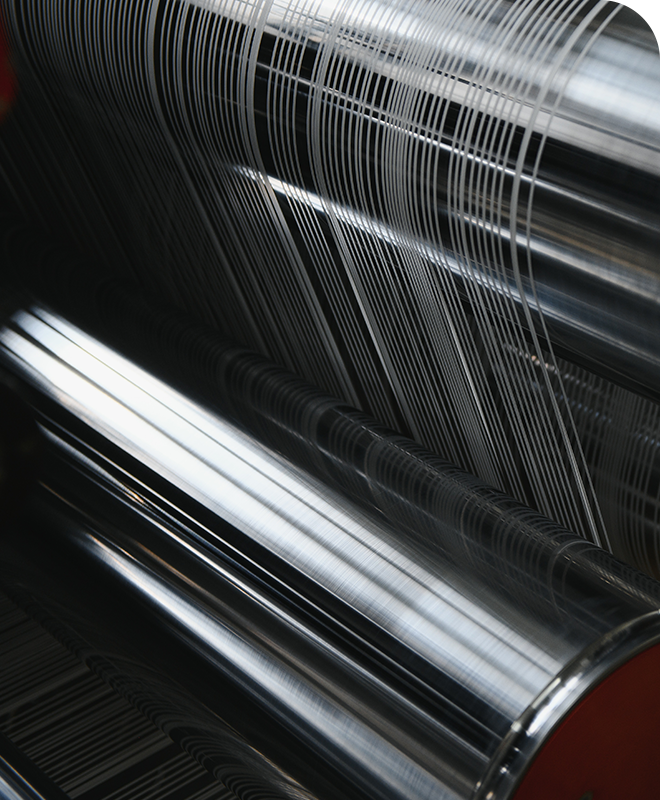

Easy processing: Plastic film can be easily processed into the required shape and size through processes such as film blowing, extrusion, and stretching.

- 6. Customization Options

Color: Transparent, translucent or colored plastic films can be customized according to customer needs.

Printing: Plastic films can be printed on the surface for brand identification and product information display, and are widely used in consumer product packaging.

Thickness and specifications: The thickness, width and roll length of the film can be customized according to specific usage scenarios and needs.

Conclusion

Plastic film has become an indispensable material for modern packaging due to its wide applicability and excellent performance, covering a variety of fields from food, industry, medicine to agriculture. Choosing plastic film with the right material can significantly improve the packaging effect of the product, and can be customized according to needs to ensure the safety, functionality and environmental protection of the packaging.

Cooperation Process

Processing Flow

Options

Materials

And

Applications

Frequently Asked Questions

Help address visitor inquiries and build a good interactive and trustful relationship with customers through information sharing.

What are the main products and services your company provides?

We mainly provide a variety of packaging products such as zipper bags, eight-side seal bags, four-side seal bags, three-side seal bags, special-shaped bags and rolls, as well as customized packaging solutions.

In which industries are your products mainly used?

Our products are widely used in food packaging, chemical packaging, beverage packaging, pharmaceutical packaging and machinery and equipment packaging industries.

What are the advantages of your packaging products?

Our products have excellent barrier properties, high strength, good printing effect and environmental protection characteristics, which can meet the diverse packaging needs of customers.

What are the characteristics of your production equipment and technology?

We are equipped with advanced blow molding machinery, printing machines, plastic compounding machines, bag making machines and other efficient production equipment, which support the processing of various materials and high-precision production processes.

How does your company ensure product quality?

We implement a strict quality control system, with strict inspection standards and processes in every link from raw material procurement to production to ensure stable and reliable product quality.

Do your packaging materials meet environmental protection requirements?

We are committed to using environmentally friendly materials, such as biodegradable bio-based plastics and recyclable materials, to meet customer demand for environmentally friendly packaging and market regulatory requirements.

How do you support customers' customization needs?

We provide customized packaging design and production services, designing and manufacturing unique packaging solutions that meet the specific needs and market trends of our customers.

What is your company's competitive advantage in the market?

We stand out with excellent product quality, flexible production capacity, professional technical support and excellent customer service, and have established a good reputation and a solid market position in the industry.

Contact Us

You can contact us in the following four ways, and we will get back to you as soon as we receive your inquiry!

Call

Send Email

Leave a Message

Add WeChat