Processing Introduction

Raw Material Preparation

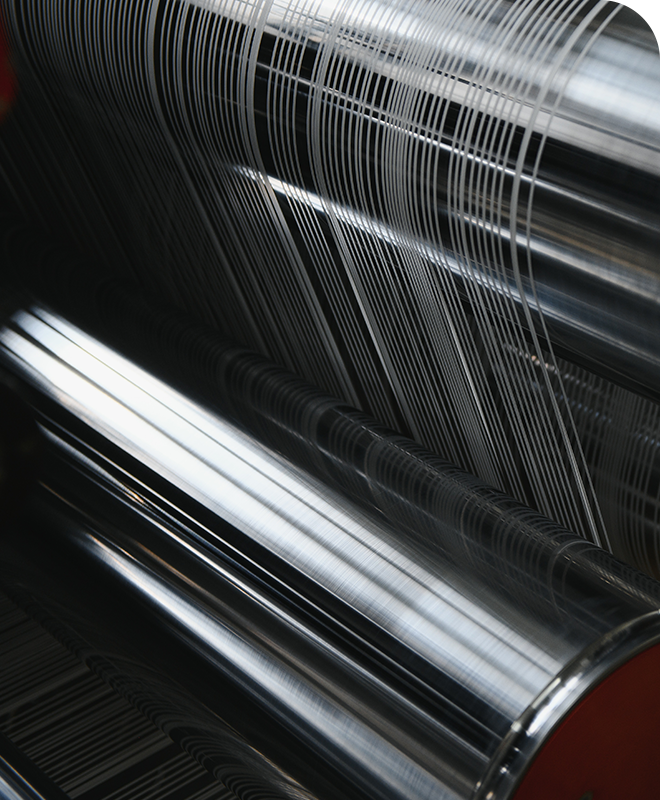

Film Blowing

Printing

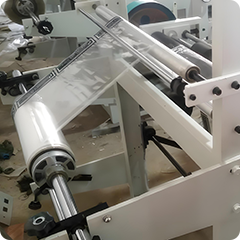

Laminating

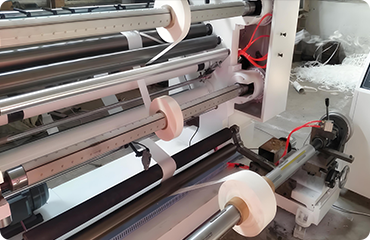

Slitting

Bag Making

Finished Product Inspection and Packaging

Customer Customization and Service

Processing Flow

Production Equipment

Our company owns multiple high-performance film blowing machines, high-speed printing machines, laminating machines, slitting machines, and bag making machines. Adhering to the business philosophy of 'Customer First, Quality Foremost, Mutual Benefit,' we are committed to building a high-end brand in the paper and plastic packaging industry.

Product Video

We are equipped with advanced blow molding machines, printing machines, plastic laminating machines, and bag making machines, supporting the processing of various materials and high-precision production processes. From raw material procurement to production, each stage has strict inspection standards and procedures to ensure stable and reliable product quality.

Options

Materials

And

Applications

Product Showroom

Product Applications

Cooperation Process

Frequently Asked Questions

Help address visitor inquiries and build a good interactive and trustful relationship with customers through information sharing.

What are the main products and services your company provides?

We mainly provide a variety of packaging products such as zipper bags, eight-side seal bags, four-side seal bags, three-side seal bags, special-shaped bags and rolls, as well as customized packaging solutions.

In which industries are your products mainly used?

Our products are widely used in food packaging, chemical packaging, beverage packaging, pharmaceutical packaging and machinery and equipment packaging industries.

What are the advantages of your packaging products?

Our products have excellent barrier properties, high strength, good printing effect and environmental protection characteristics, which can meet the diverse packaging needs of customers.

What are the characteristics of your production equipment and technology?

We are equipped with advanced blow molding machinery, printing machines, plastic compounding machines, bag making machines and other efficient production equipment, which support the processing of various materials and high-precision production processes.

How does your company ensure product quality?

We implement a strict quality control system, with strict inspection standards and processes in every link from raw material procurement to production to ensure stable and reliable product quality.

Do your packaging materials meet environmental protection requirements?

We are committed to using environmentally friendly materials, such as biodegradable bio-based plastics and recyclable materials, to meet customer demand for environmentally friendly packaging and market regulatory requirements.

How do you support customers' customization needs?

We provide customized packaging design and production services, designing and manufacturing unique packaging solutions that meet the specific needs and market trends of our customers.

What is your company's competitive advantage in the market?

We stand out with excellent product quality, flexible production capacity, professional technical support and excellent customer service, and have established a good reputation and a solid market position in the industry.

Contact Us

You can contact us in the following four ways, and we will get back to you as soon as we receive your inquiry!

Call

Send Email

Leave a Message

Add WeChat