Product

All Product Categories

plastic bag

Plastic bags are an indispensable tool in modern packaging and transportation. They are widely used in daily life and various industries due to their advantages such as lightness, durability and low cost. The following is the product details of plastic bags, including common materials, characteristics, application scenarios and environmental protection trends.

Product Video

Product Catalog

- 1. Material classification

Plastic bags are divided into the following categories according to different materials:

Polyethylene (PE) plastic bags:

- Classification:

Low-density polyethylene (LDPE): soft, high transparency, cold-resistant, suitable for food and daily necessities packaging.

High-density polyethylene (HDPE): high hardness, strong toughness, tear resistance, usually used for shopping bags and garbage bags.

Features: non-toxic and odorless, waterproof, dustproof, acid and alkali resistant, strong chemical stability.

- Polypropylene (PP) plastic bags:

Features: high transparency, good heat resistance, light specific gravity, smooth surface and tear resistance.

Polyvinyl chloride (PVC) plastic bags:

Features: good flexibility, high transparency, waterproof, durable, but not environmentally friendly, may release harmful substances at high temperatures.

2. Characteristics of plastic bags

Lightweight: Plastic bags are light in weight, easy to carry and use, and are particularly suitable for packaging and transporting various lightweight items.

Waterproof: Plastic bags can effectively isolate moisture and are widely used in packaging food, liquid products and humid environments.

Flexibility and durability: Plastic bags are highly flexible and tear-resistant, especially HDPE bags, which are suitable for carrying heavier items.

Transparency: Plastic bags have different transparency depending on the material. PP and LDPE plastic bags have higher transparency and are suitable for display packaging; HDPE plastic bags have lower transparency but stronger toughness.

Chemical stability: Plastic bags are acid-resistant and alkali-resistant, not easily corroded by chemicals, and are suitable for packaging chemical products.

- 3. Specifications and sizes

Thickness: The thickness of plastic bags varies depending on the purpose of use. Shopping bags and food bags are usually 15 to 40 microns, while industrial packaging bags or thickened garbage bags can be 50 to 100 microns thick.

Size: The size of plastic bags can be customized, with common sizes ranging from small bags of 20cm×30cm to large bags of 100cm×120cm, to meet various packaging needs.

- 4. Environmental protection and sustainable development

With the increasing awareness of environmental protection, traditional plastic bags have caused many environmental problems due to their difficulty in degradation. To solve this problem, the plastic bag industry is gradually moving towards the following environmentally friendly directions:

Degradable plastic bags: Plastic bags made of biomaterials such as PLA can be naturally degraded within a certain period of time, reducing plastic pollution.

Reusable plastic bags: More solid and durable plastic bag designs encourage consumers to reuse and reduce the demand for disposable plastic bags.

Thin design: By improving the process and materials of plastic bags, the amount of plastic used is reduced, but the original functionality is still maintained.

- 5. Customization options

Plastic bags can be customized according to customer needs, including:

Color: Transparent, white or colored plastic bags can be produced, depending on the brand image and product requirements.

Printing: Brand logos, product information or advertisements can be printed on plastic bags, which are widely used in retail and commercial packaging.

Thickened or reinforced design: In order to adapt to different uses, plastic bags can be thickened, strengthened handles and other designs to increase their carrying capacity.

- 6. Advantages and disadvantages

Advantages:

Lightweight and low cost.

Waterproof and dustproof, suitable for various packaging.

Can be customized in a variety of colors and sizes to meet different needs.

Disadvantages:

Not environmentally friendly, traditional plastic bags have a long degradation cycle and are prone to white pollution.

Some plastic bags may release harmful substances at high temperatures and are not suitable for packaging high-temperature foods.

- Conclusion

As a widely used packaging material, plastic bags play an important role in daily life and various industries due to their lightness, durability and low cost. With the increase of environmental awareness, degradable plastic bags and reusable plastic bags will become an important trend in the plastic bag industry in the future. Choosing plastic bags of suitable materials and specifications can not only improve the packaging effect, but also reduce the impact on the environment.

Cooperation Process

Processing Flow

Options

Materials

And

Applications

Frequently Asked Questions

Help address visitor inquiries and build a good interactive and trustful relationship with customers through information sharing.

What are the main products and services your company provides?

We mainly provide a variety of packaging products such as zipper bags, eight-side seal bags, four-side seal bags, three-side seal bags, special-shaped bags and rolls, as well as customized packaging solutions.

In which industries are your products mainly used?

Our products are widely used in food packaging, chemical packaging, beverage packaging, pharmaceutical packaging and machinery and equipment packaging industries.

What are the advantages of your packaging products?

Our products have excellent barrier properties, high strength, good printing effect and environmental protection characteristics, which can meet the diverse packaging needs of customers.

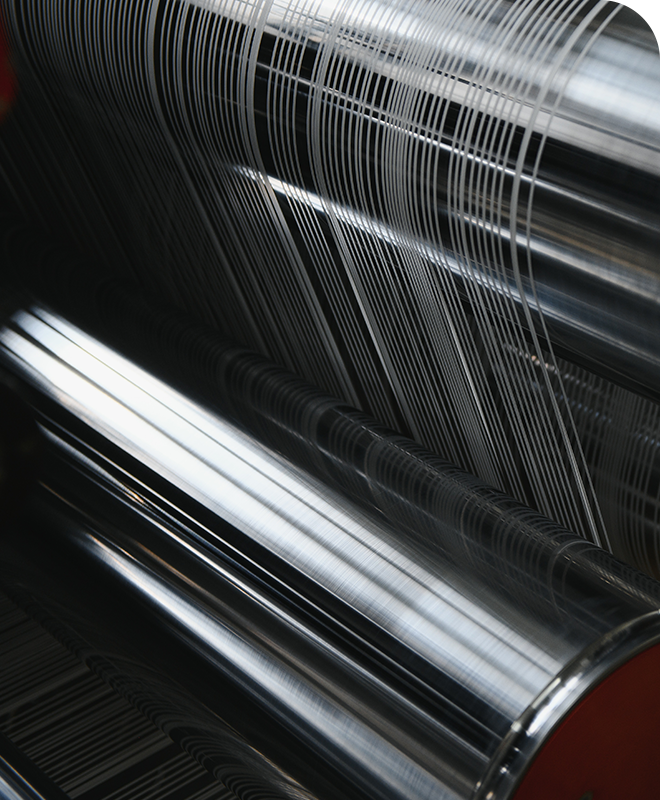

What are the characteristics of your production equipment and technology?

We are equipped with advanced blow molding machinery, printing machines, plastic compounding machines, bag making machines and other efficient production equipment, which support the processing of various materials and high-precision production processes.

How does your company ensure product quality?

We implement a strict quality control system, with strict inspection standards and processes in every link from raw material procurement to production to ensure stable and reliable product quality.

Do your packaging materials meet environmental protection requirements?

We are committed to using environmentally friendly materials, such as biodegradable bio-based plastics and recyclable materials, to meet customer demand for environmentally friendly packaging and market regulatory requirements.

How do you support customers' customization needs?

We provide customized packaging design and production services, designing and manufacturing unique packaging solutions that meet the specific needs and market trends of our customers.

What is your company's competitive advantage in the market?

We stand out with excellent product quality, flexible production capacity, professional technical support and excellent customer service, and have established a good reputation and a solid market position in the industry.

Contact Us

You can contact us in the following four ways, and we will get back to you as soon as we receive your inquiry!

Call

Send Email

Leave a Message

Add WeChat